Brief Description

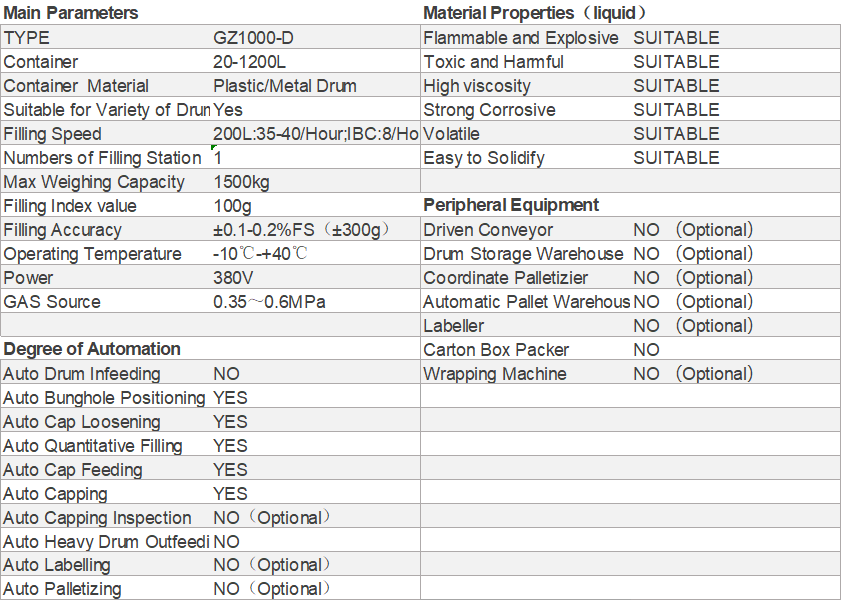

GZ1000-D is able to realize the automation of forklift pallet upload, auto cap loosening, auto bunghole positioning, auto quantitative filling, auto capping and forklift heavy pallet out. D series auto positioning can choose visual or electromechanical tech according to the container type. If AGV cars are enabled, D series can realize factory unmanned. Sealed filling room, multi nozzles, driven rollers, ex-proof motor, air extraction equipment and safety fence are optional.

Equipment features:

Automatically complete whole filling process, labor saving

One machine adaptable to various containers and various material, more flexible

Capping with constant torque, applicable to both plastic and steel containers

Sealed filling room suitable for toxic, harmful and volatile material

Able to be equipped with long driven roller to realize labelling, wrapping and container outfeed

Usually 1-2 stations, speed up to 70-80/h for 200L drum, and 16-20/h for IBC